Why install solar panels on 100 different rooftops when we can build a massive infrastructure designed for peak efficiency?

At Linearsun®, we have mastered the cycle:

We Manufacture: High-resistance aluminum mounting structures built to last for decades.

We Install: Turnkey solutions backed by local engineering and craftsmanship.

The Next Step: Our first 300 kWp Community Solar Farm.

🚀 The Innovation: We are developing a digital ecosystem where the energy generated at our farm is converted into digital offset assets.

Very soon, businesses and households will be able to “own” a share of our generation without installing a single bolt on their properties. You acquire the digital participation; we handle the metal, the panels, and the grid injection.

It’s real energy, installed by professionals, managed with cutting-edge technology.

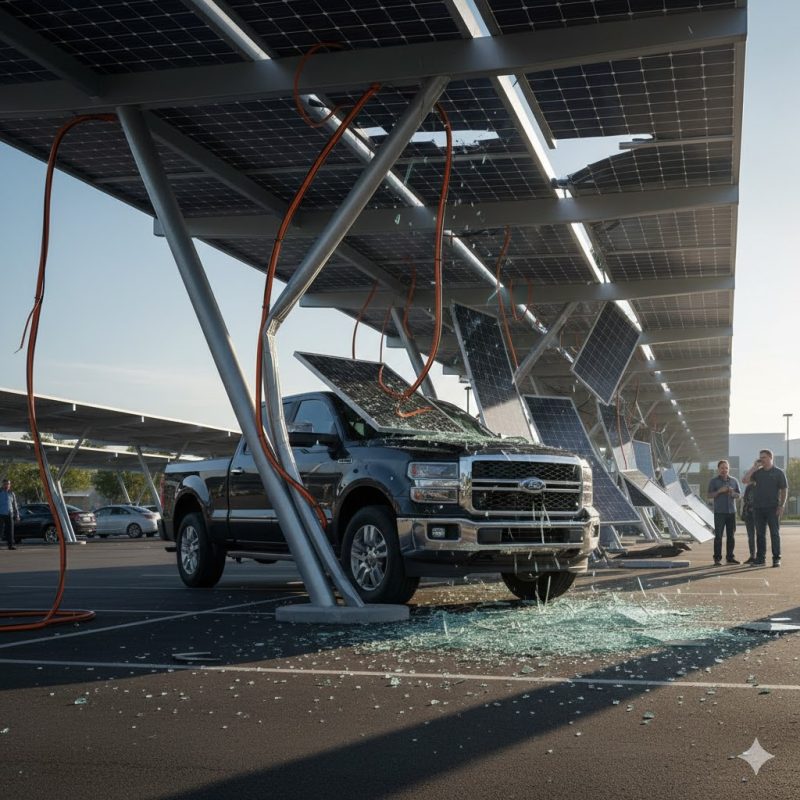

Solar Carports: Crystal Elegance on Feet of Clay

Walking through a parking lot covered by solar panels feels like stepping into the future. On paper, it’s the perfect solution: you protect vehicles from the sun, generate clean energy, and make use of previously dead space. However, behind that minimalist steel and glass aesthetic lies a structural weakness that many prefer to ignore: an absolute lack of resistance to human error.

The problem with modern solar carports is that they have been designed as power generation structures, not as road infrastructure. In the quest to optimize costs and maximize solar collection area, the supports have become alarmingly thin.

The Fragility of “Clean” Design

In modern architecture, less is more. But in a parking lot—where tons of moving metal are operated by tired, distracted people with limited visibility—”less” can be an imminent disaster.

Most of these structures lack real perimeter protections. We see slender steel columns holding tons of panels and wiring over our heads, yet they lack the impact absorption capacity of a concrete bollard. A simple miscalculation while reversing, a side-swipe from a truck, or a driver losing control for a split second can compromise the integrity of an entire row of panels.

A Domino Effect of Glass and Silicon

Unlike a concrete roof or a traditional garage structure, a solar carport is a high-voltage system. An impact on a column doesn’t just risk physical collapse; it involves high-voltage DC cables that can be severed, causing short circuits and fire hazards in an area full of fuel tanks.

We are installing cutting-edge technology on supports that look like toothpicks compared to the vehicles they are meant to house. They look great—as long as no one touches them. But in the real world, vehicles hit things. It’s an inevitable statistic.

Conclusion: Aesthetics or Safety?

This isn’t about being against solar energy; it’s about demanding engineering that understands its environment. A solar carport should be, first and foremost, a robust structure capable of surviving the dynamics of a parking lot. Until we see reinforced steel guards or concrete bases protecting the supports, these technological marvels will remain a risky bet.

A parking lot is not an art gallery; it’s a maneuver zone. And it’s time for solar carport design to start treating it as such.

Solar Longevity: Benefits of Stainless Steel Fasteners in Aluminum Structures

In the photovoltaic industry, structural durability is as critical as panel efficiency. The choice of fasteners is not a minor detail; it is the factor that ensures the system withstands decades of outdoor exposure. Below, we analyze why the combination of raw aluminum and stainless steel is the superior technical choice.

1. Prevention of Galvanic Corrosion

Aluminum and stainless steel have compatible electrochemical potentials, reducing the risk of galvanic coupling compared to carbon or galvanized steel. Stainless steel develops a passive chromium oxide layer that minimizes electrolytic reactions, protecting the integrity of the aluminum profiles.

2. Mechanical Strength and Fatigue

Solar structures are subjected to dynamic loads such as wind gusts and thermal expansion. Stainless steel maintains its toughness under extreme temperature changes, and its relative elasticity allows the joint to withstand aluminum’s expansion cycles without losing torque or fracturing.

3. Aesthetics and Zero Maintenance

Unlike zinc-plated screws, stainless steel does not produce “brown rust streaks” that permanently stain aluminum profiles. This ensures a visually flawless installation and eliminates the need for coatings or inspections due to material degradation.

4. Material Comparison

While galvanized steel relies on a sacrificial zinc layer that depletes over time (especially in humid environments), stainless steel is intrinsically resistant throughout its mass, guaranteeing a lifespan exceeding the 25 to 30 years required in solar projects.

5. Grade Selection: A2 (304) vs. A4 (316)

Location is key:

- Grade A2 (304): Ideal for standard rural or urban environments.

- Grade A4 (316): “Marine grade.” It contains molybdenum to resist chlorides. It is mandatory for installations within 5 km of the coast or in aggressive industrial areas.

6. Managing “Galling” or Seizing

Stainless steel is prone to galling (cold welding due to friction). To prevent it:

- Use nickel or ceramic-based anti-seize lubricants (never copper-based, which reacts with aluminum).

- Avoid high-RPM impact tools.

- Keep threads free of sand or dust.

7. Synergy Summary

The combination of aluminum (lightweight and natural resistance) with stainless steel (strength and chemical passivity) creates an eternally structural system. It also facilitates future maintenance, allowing bolts to be loosened decades later without being welded shut by corrosion.

8. Cost-Benefit Analysis

Although stainless steel fasteners may cost 2 to 3 times more than galvanized ones, their impact on the total project budget is usually less than 1%. This minimal initial investment saves 100% of long-term structural replacement costs and corrosion-related failures.

¿Sabías que la seguridad de tu parque solar depende de una pieza de pocos centímetros? ⚙️

Hablamos de las Omegas de aluminio (también conocidas como Clamps o Mordazas). Son los accesorios que fijan los paneles a la estructura, garantizando que soporten vientos, dilataciones térmicas y el paso del tiempo.

En Linearsun, integramos la ingeniería eléctrica con la fabricación metalúrgica para ofrecerte un componente superior:

✅ Aluminio de alta resistencia: Sin riesgo de corrosión y con máxima durabilidad. ✅ Diseño Propio: Desarrolladas para un ajuste milimétrico que protege el marco del panel. ✅ Producción Nacional: Fabricamos en San Luis para proyectos de todo el país.

Entendemos que cada obra tiene sus tiempos. Por eso, nuestra producción es planificada para cumplir con los estándares de calidad más exigentes.

🔹 Consulte por plazos de entrega según el volumen de su proyecto.

👇 Encuentre todas las especificaciones técnicas aquí: https://linearsun.com/?page_id=246